Ken,

thanks for the compliment, but I'm no master modeler. I just try my best, and love what I'm building. The love really does help.

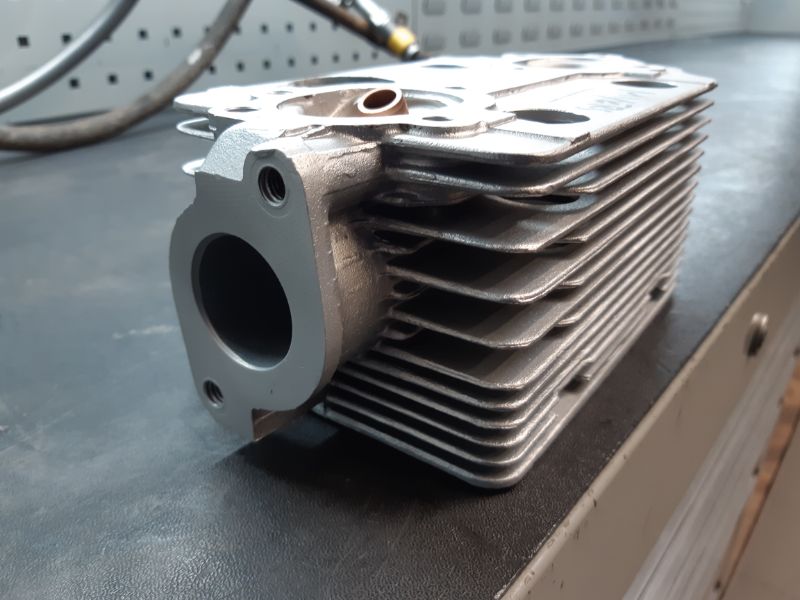

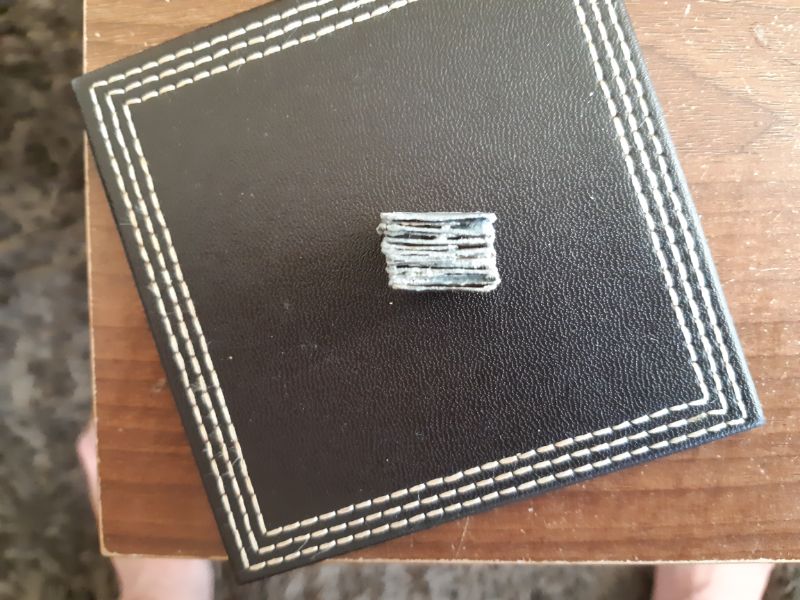

As for your cylinder head issues, I'm sure you guys are right in that the water based glue was the cause of the issue. I'm just not so sure that working with little pcs of Aluminum would be much easier as cutting them out seems like really hard task. Why not try using Evergreen plastic sheet stock. It comes sever thicknesses. I've got .010, .020, & .040. Most likely the .020 would be more of what you're looking for. It's very easy to cut as I use a Mister Chopper II, to square of the pcs, then just sand and or file to shape. For the spaces you can just use a punch set.

Having direct access to the car is a dream come true. Can you actually seat in it? Now that's inspiration for sure.

Joel