Thanks Damian.

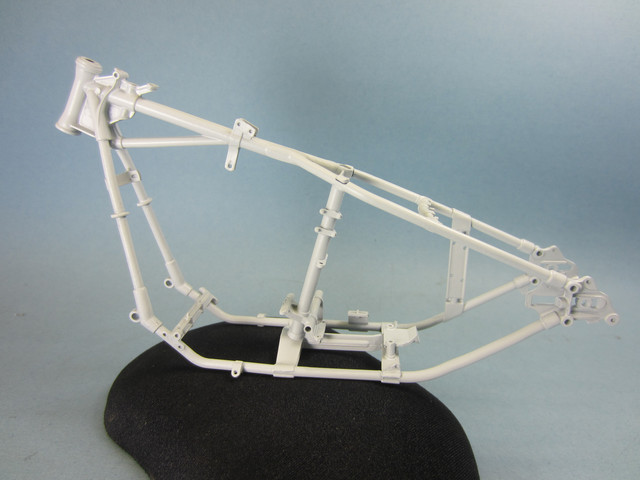

My industry experience afforded me first hand and hands on of some of these bikes. The frames especially , me being lucky enough to work for a world renowned Harley frame straightening shop. I fell in love with the frames , they re the genesis of chopper building.

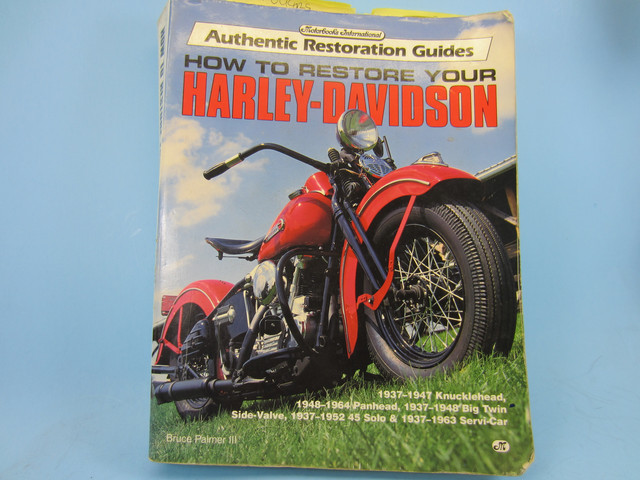

However that not being the case here as this will be a stocker.

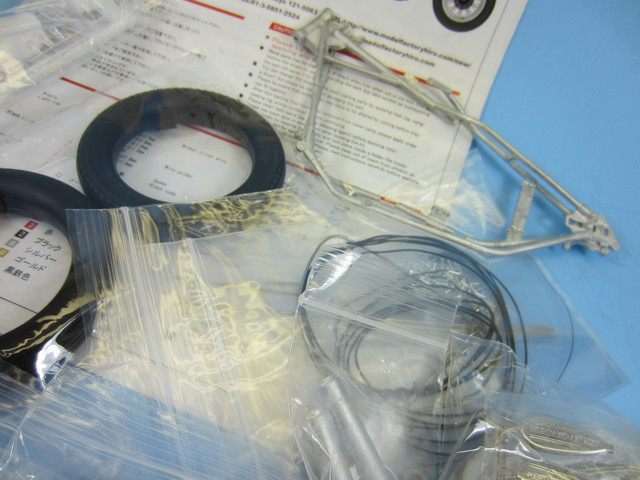

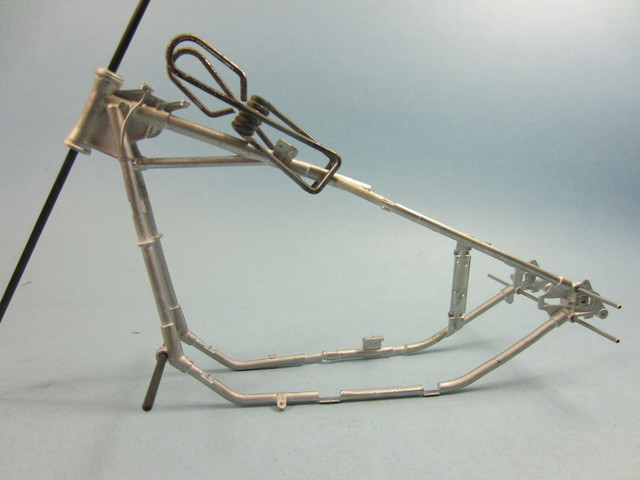

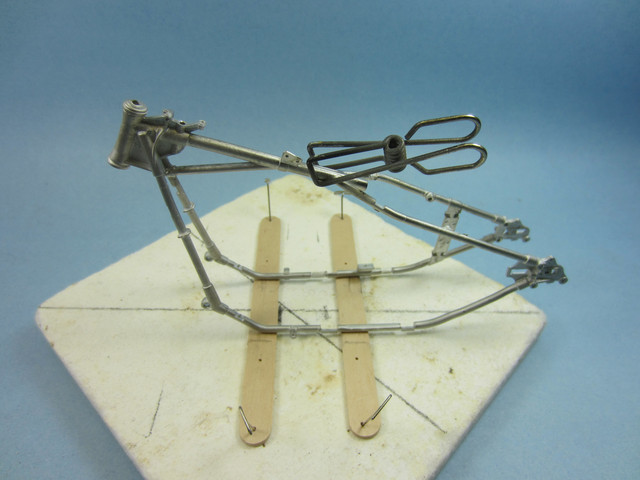

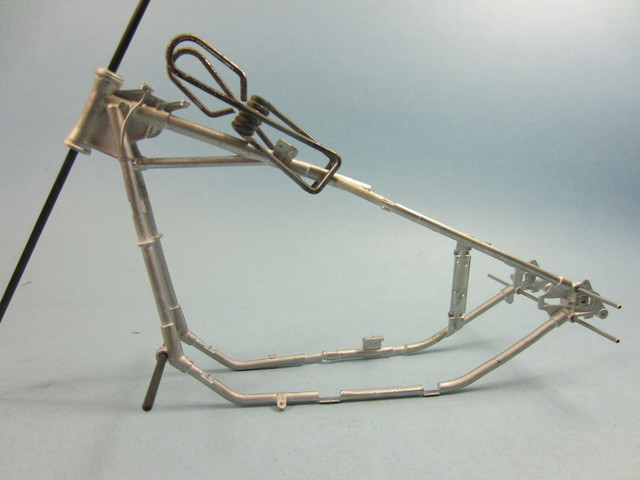

The frame presents some of the most difficult part of this model. The parts breakdown is excellent , going by the real components themselves. The probs occur in the way that the main frame rails are cast to accept the components. My best advice is to not handle the frame at all until yer gonna build it. I did and put it outta kilter.

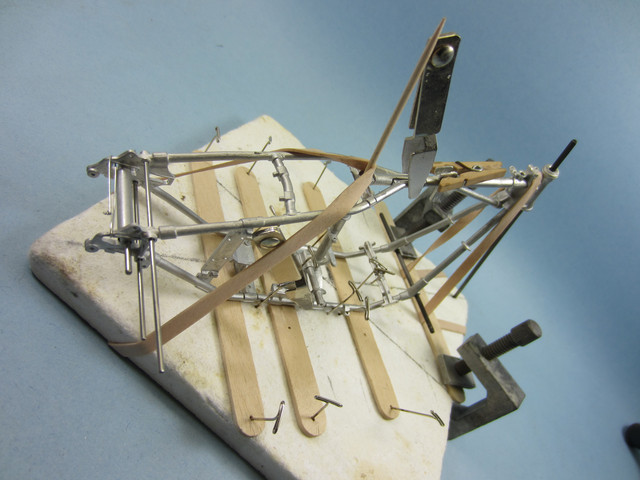

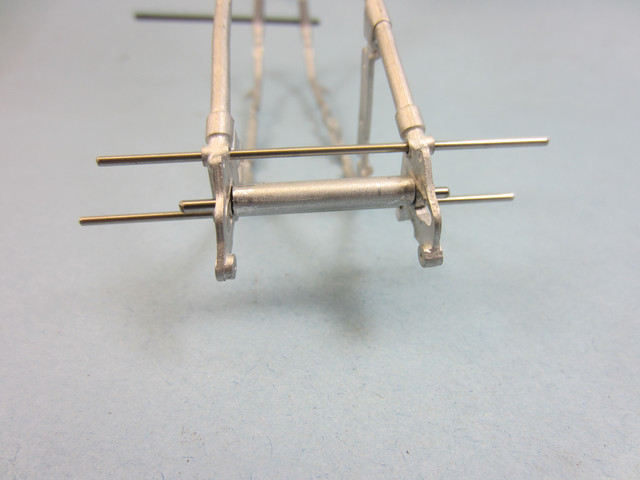

Here the frame has been drilled as an existing one would be and rods inserted to align the parts:

BOOM! Pretty much aligned as it would have been at the factory.

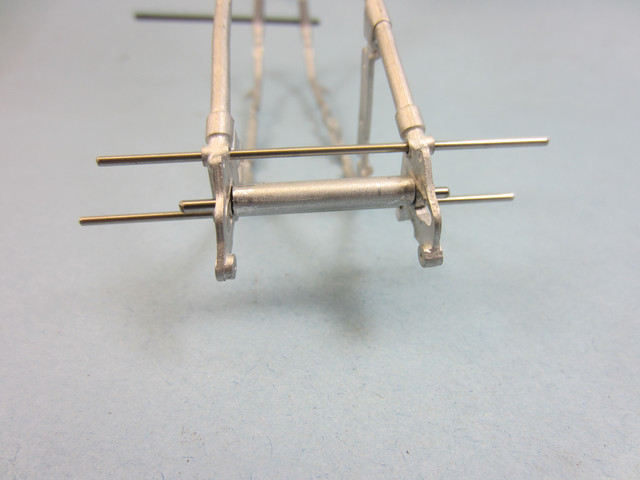

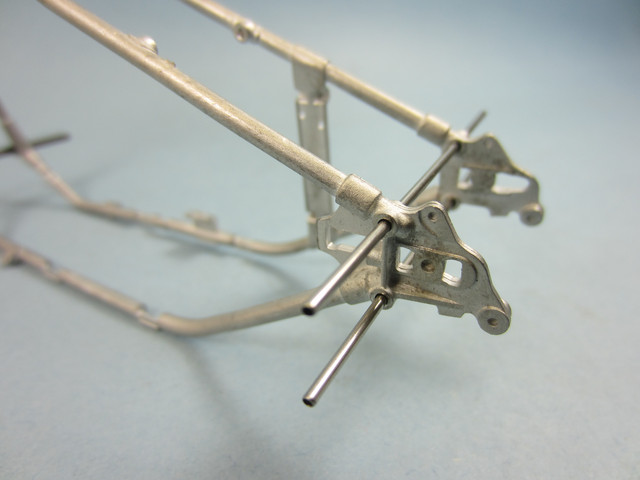

2mm carbon rod and .050 " s/s tube:

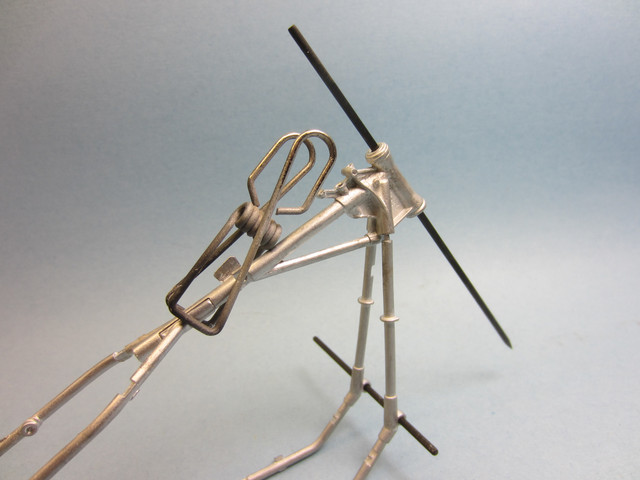

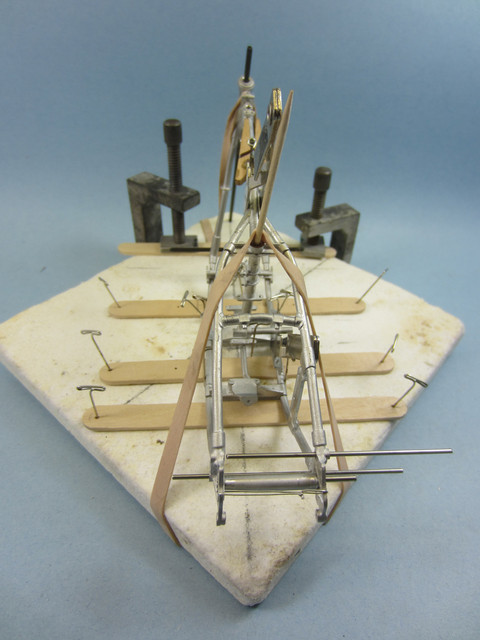

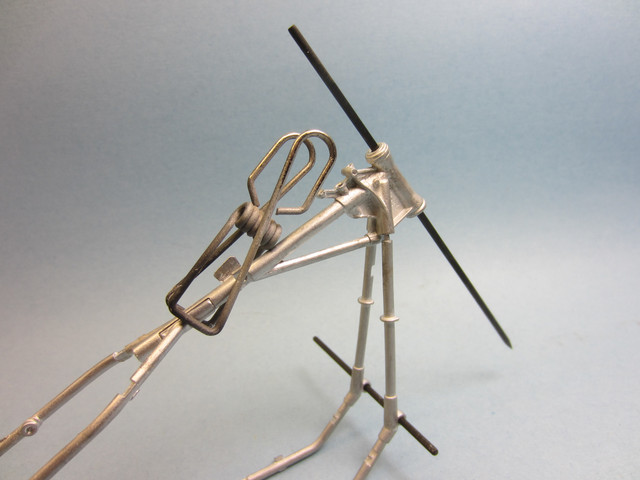

I made a neck alignment tool for S&G's.

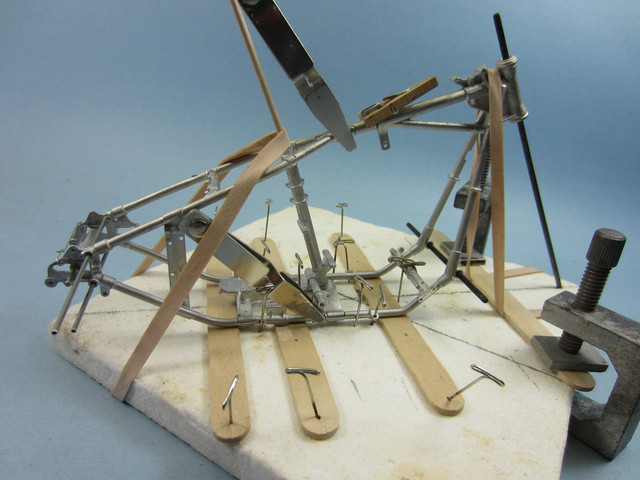

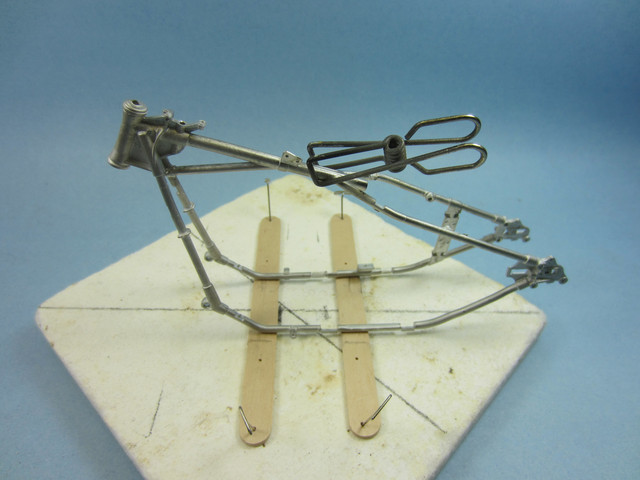

Also a flat jig on the soldering pad gets some work:

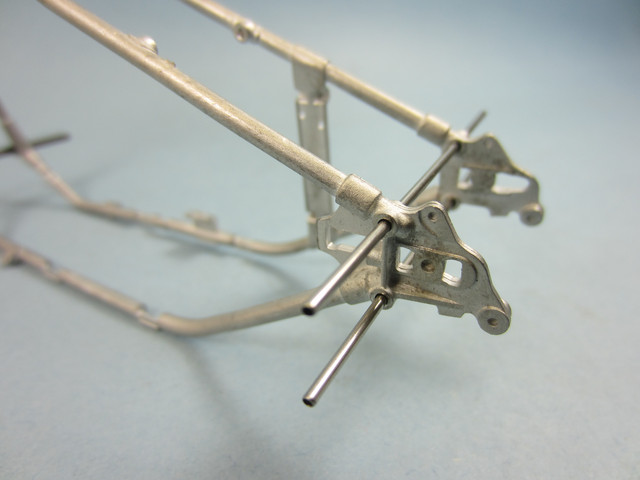

Final work stabilizing the rear of the frame. There is no way this is gonna move or de-align as the frame gets jigged:

A piece of tube cut to the width of the wheel components as a spacer and a 1/16 s/s tig rod piece for an 'axle'.

Heavy concentration here , but no gluing. I tested some of the metal and it can be soldered, that's where we are going here.