British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Saturday, September 17, 2016 - 01:21 AM UTC

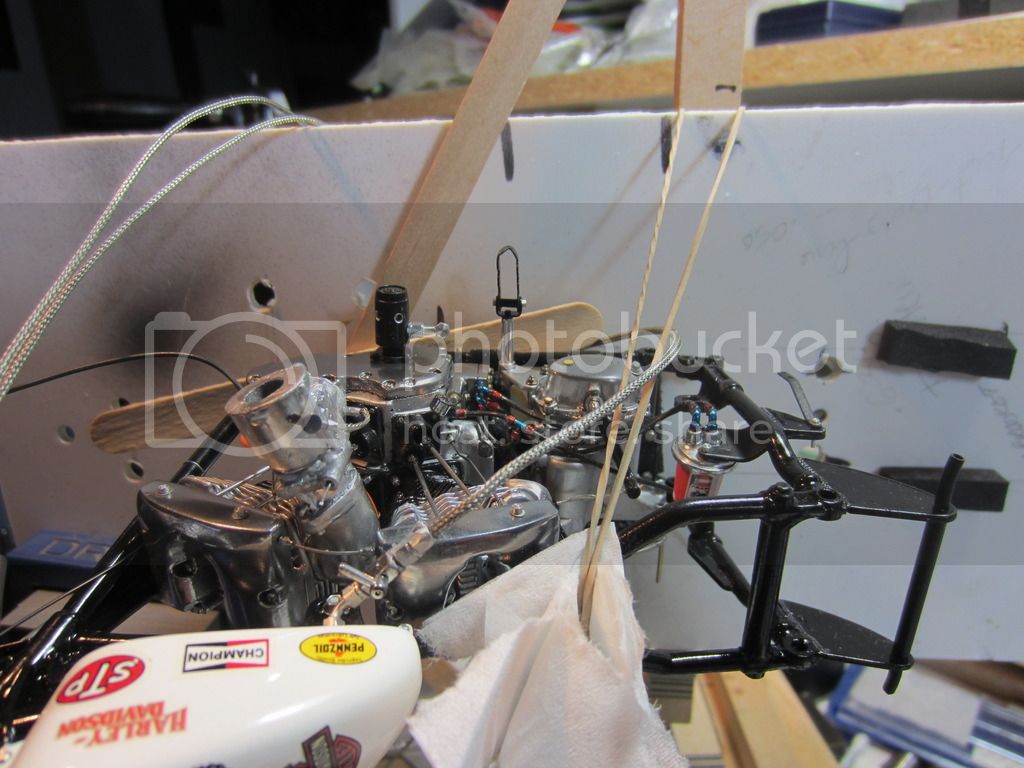

...and the front brake line:

As well as the lanyard that connects the rider to the machine , and kills the machine in the case of rider ejection:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Saturday, September 17, 2016 - 10:41 PM UTC

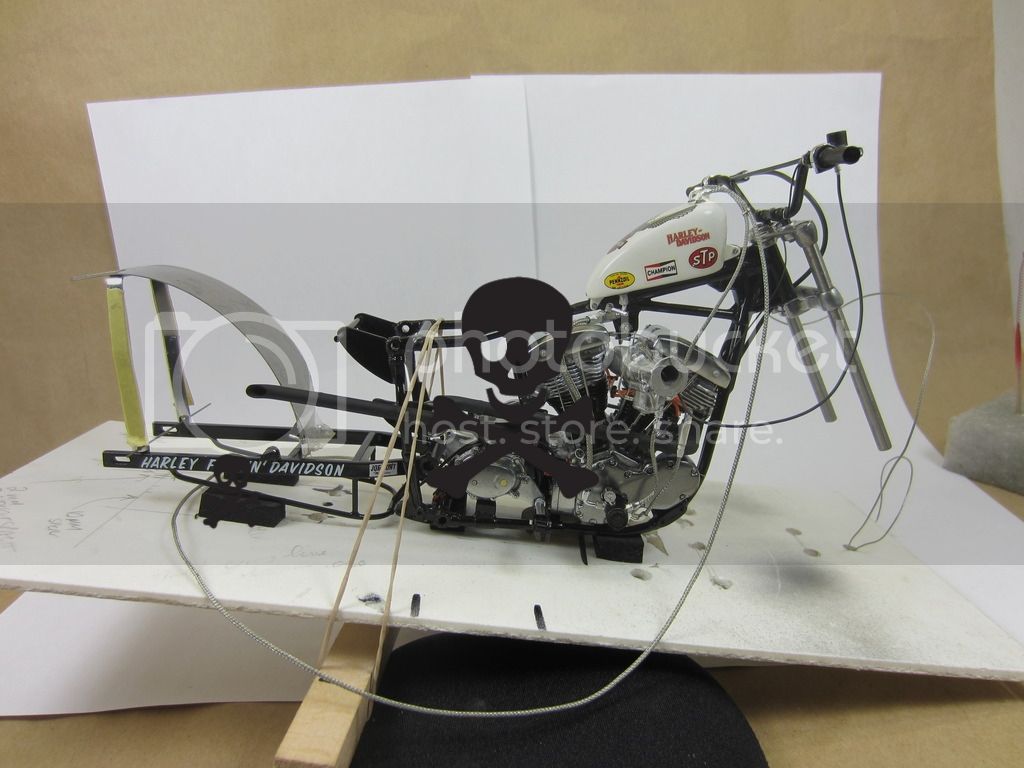

Vertical integration allows footpeg alignment:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Sunday, September 18, 2016 - 12:03 AM UTC

And exhaust pipe fitment begins:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Sunday, September 18, 2016 - 08:17 AM UTC

Pipe lineup tricky , so a little simple jig set up to keep the pipes semi-straight while the epoxy dries:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Sunday, September 18, 2016 - 12:17 PM UTC

Best procedure appears to be to mount all of the fittings for the fuel lines etc, first then fit the lines. So the pump gets a gauge , a feed a tank return and a carb feed , the carb gets a return fitting and a feed:

And the axles and swingarm bolt get chromed, the kill lanyard gets red:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Monday, September 19, 2016 - 12:53 AM UTC

Pipes get mounted:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Wednesday, September 21, 2016 - 11:34 AM UTC

Rear fender and strut mated to the swingarm:

Exhaust mounting completed , and the fuel system ahs one more connection to complete:

Going well at 9500.

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Thursday, September 22, 2016 - 02:44 AM UTC

Test fitting tomfoolery:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Thursday, September 22, 2016 - 06:14 AM UTC

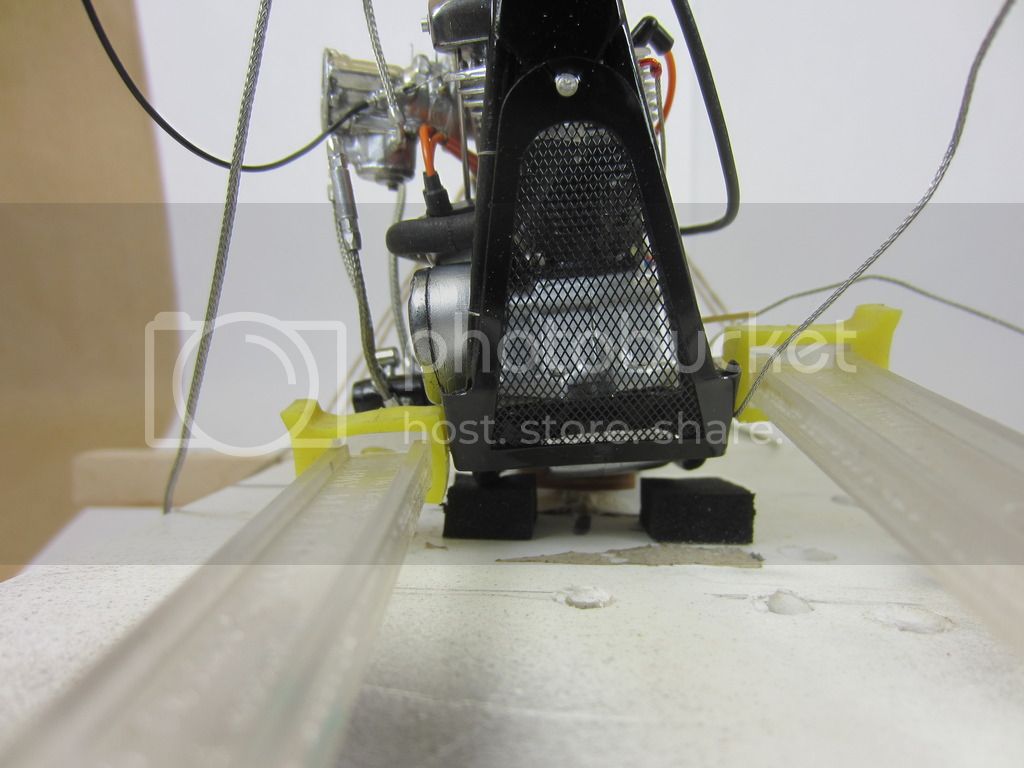

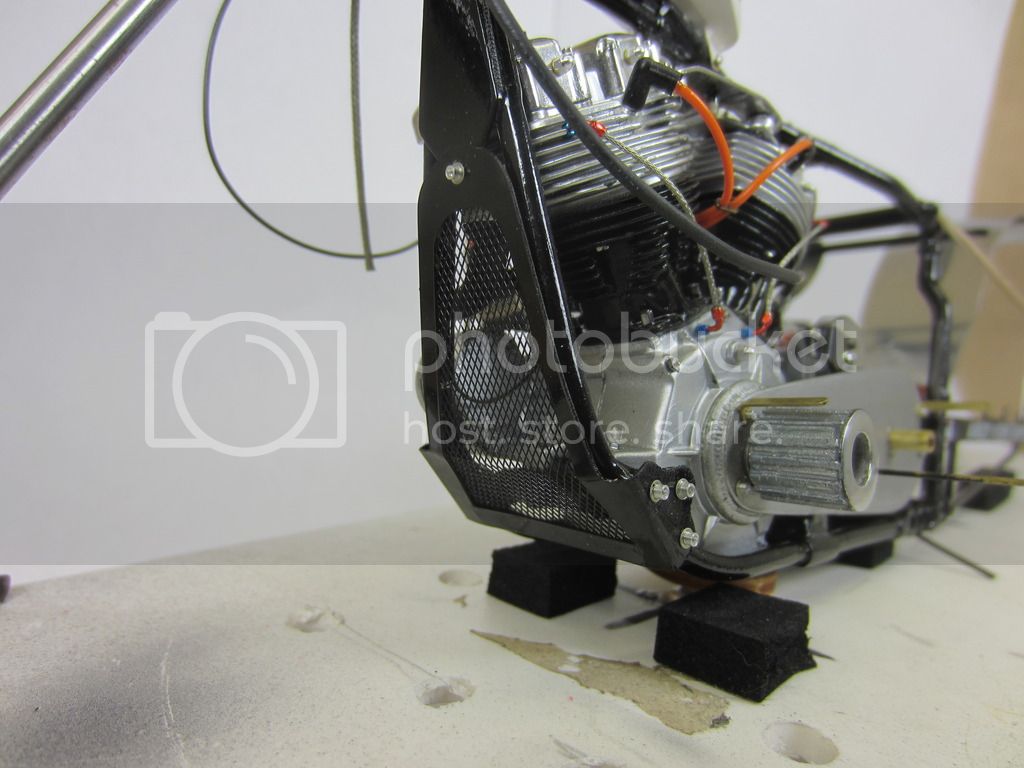

Grilled:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Thursday, September 22, 2016 - 10:11 AM UTC

Front grill in place with hardware:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Friday, September 23, 2016 - 11:54 PM UTC

Bad news first my chain assy tools and parts have turned out to be unworkable. I wont go into the details as I' already pi$$ed enough!

Good news is my 1/9 Brough kit , with a white metal and p/e chain set works on my sprockets and has been substituted for the useless parts. MFH offers these separate now so 2 more ordered to make up the extended Hillclimber chain.

Chain assy in progress:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Saturday, September 24, 2016 - 05:42 AM UTC

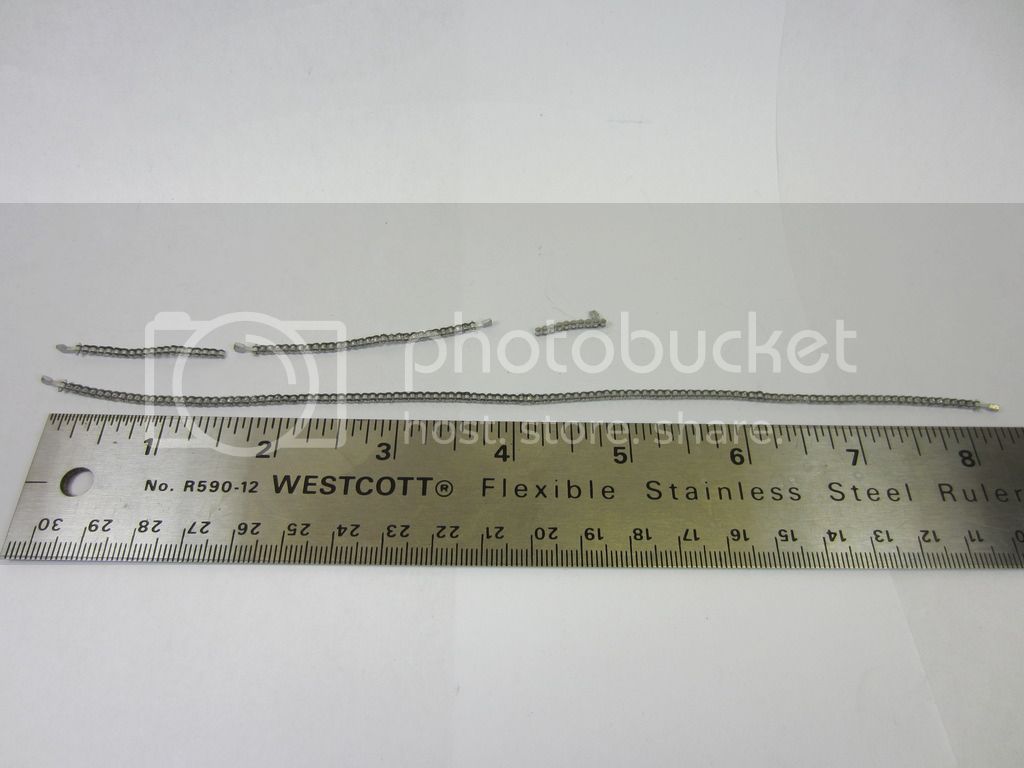

20 - 30 minutes per section , 4 sections make an 8 inch Hillclimber chain:

Solves a big headache- thanks MFH!

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Saturday, September 24, 2016 - 11:10 AM UTC

Naturally chain run and wheel spacing follows:

Everything looks good work can progress in the rear wheel dept.

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Sunday, September 25, 2016 - 01:03 AM UTC

An extended swingarm/chain run would need a guide, usually underneath close to the rear sprocket. Here is one with a leftover sprocket, this will keep the chain in line on its way to the wheel sprocket:

On top it the chain run would need a Teflon pad or guide, as the chain is loose until the rider is on board and power is applied. Here is one out of plastic box section:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Sunday, September 25, 2016 - 12:03 PM UTC

Primary drive pully's and belt on , inner tooth detail added:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

Namabiiru

Associate Editor

Associate Editor

#399

Rhode Island, United States

Joined: March 05, 2014

KitMaker: 2,888 posts

Auto Modeler: 32 posts

Posted: Sunday, September 25, 2016 - 04:54 PM UTC

Really starting to shape up, Steve. Looks fantastic!

Out of curiosity, roughly what percentage of the mass of this thing is actually metal, rather than plastic/resin/etc.?

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Sunday, September 25, 2016 - 09:44 PM UTC

The piece has all metal wheels, top motor mount , primary drive top cover , primary plate , entire swingarm , exhaust pipes , fork tubes , handlebars , rear fender , axles , swingarm bolt , shocks , footpegs , clutch collar and fuel pump are all metal of some type.

Thanks for your interest and having the jam tarts to comment.

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Monday, September 26, 2016 - 02:42 AM UTC

Assy progess':

Playin' the duck on wheel work...

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Monday, September 26, 2016 - 11:29 PM UTC

Velocity stack and chain run guide get some work:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Tuesday, September 27, 2016 - 02:48 AM UTC

Primary drive complete to the detail wash stage:

And the chain guide gets mounted:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Tuesday, September 27, 2016 - 07:48 AM UTC

Forking progress:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Tuesday, September 27, 2016 - 09:35 AM UTC

Rotor and caliper matrix aligned, as well as wheel spacing:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Wednesday, September 28, 2016 - 03:07 AM UTC

Final assy in progress for the next few days. Rims are painted and drying , wheel spacing done. I will shortly have a chassis sans wheels. This is good.

This thread will be sealed off within 2 weeks so get some now!!

Test fitting repeatedly on a Frankenstien piece of this nature is by far the best advice. I feel huge strain & stress

as I move through installing the final parts on the as it is, having to modify at the last minute is hair-raising to say the least.

So the seat plopped on without much fanfare or panty-knotting:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

British Columbia, Canada

Joined: March 16, 2010

KitMaker: 473 posts

Auto Modeler: 257 posts

Posted: Thursday, September 29, 2016 - 12:23 AM UTC

10,000

Pretty good for a 'sickle blog.

Wasn't gonna go too fancy on the base, but a quick check of my burl stock and I found this:

Locally sourced birds eye maple burl , planed and sanded , I'll be soaking it in polyurethane clear to bring out the detail.

Checking:

fbook : Custom Motorcycle Modeler Page

Thank you , Steve

Florida, United States

Joined: May 14, 2012

KitMaker: 730 posts

Auto Modeler: 14 posts

Posted: Thursday, September 29, 2016 - 02:02 AM UTC

Just chkd in again and went back thru the pgs for a refresh.

Wadda fr'kn Masterpiece Steve, thanks for posting.

I, for one, would be interested in any marketing you may be heading for.

Cheers

Dave

"No beast so fierce but knows some touch of pity.

But I know none, and therefore am no beast."